Air compressors are an essential piece of equipment for many industrial businesses. One type of air compressor that is particularly useful is the two stage air compressor. This type of air compressor is uniquely designed to provide a high level of air pressure and output, making it an ideal choice for a variety of applications. In this article, we’ll look at what a two stage air compressor is and what you need to know about them. A two stage air compressor is an industrial machine that works by taking in air, compressing it, and delivering it with a high level of pressure. This type of air compressor is capable of producing pressures of up to 250 PSI, making it ideal for a variety of applications such as powering pneumatic tools, inflating tires, and even filling up scuba tanks. Not only is a two stage air compressor powerful, but it is also efficient, saving energy and money in the long run. In this article, we’ll discuss the features and benefits of a two stage air compressor and how they can be used.

What is a 2 Stage Air Compressor?

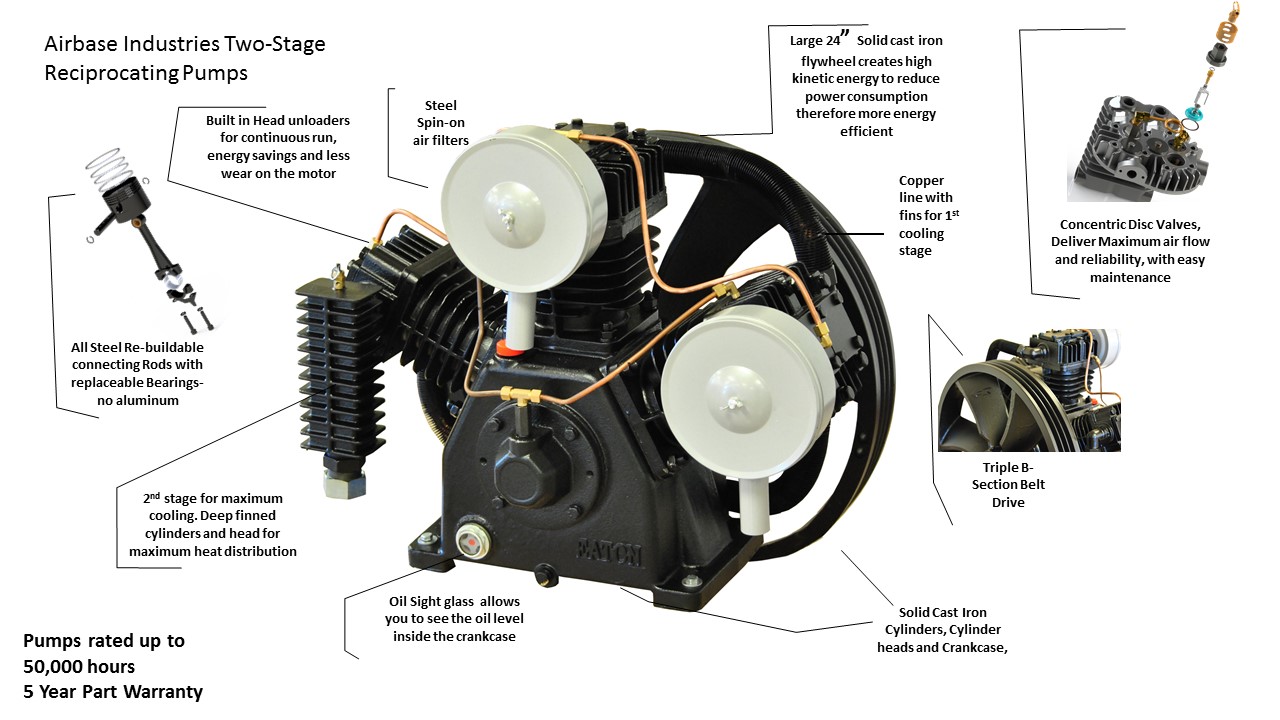

A two-stage air compressor is an air compressor that uses two separate stages to compress air. The first stage uses a piston to compress air to a certain pressure. The air then passes through a second stage which increases the pressure even further. The result is a higher pressure air stream which can be used for a variety of purposes, from powering air tools to powering air cylinders. Two-stage air compressors are typically more efficient than single-stage compressors, and are usually used for industrial applications such as powering air tools. They are also more expensive than single-stage compressors, but the increased efficiency often makes them a better long-term investment. Additionally, two-stage compressors are often more reliable since they have fewer moving parts than single-stage compressors.

Advantages of a 2 Stage Air Compressor

A 2 stage air compressor is an economical and efficient way to provide compressed air for various applications. The two stages of the compressor work in tandem to provide higher air pressure and greater air volume than a single-stage compressor. This makes them ideal for industrial or commercial applications that require a large amount of compressed air. The primary benefit of a 2 stage air compressor is its ability to provide higher air pressure and greater air volume than a single-stage compressor. The two stages of the compressor allow it to reach higher pressures more quickly and efficiently than a single-stage compressor. Additionally, the two stages provide greater air volume, which is beneficial for applications requiring more air pressure. The two-stage compressor is also quieter than a single-stage compressor, making it a better choice for applications where noise levels are a concern. Finally, the two-stage compressor is more energy efficient than a single-stage compressor, which can help reduce operating costs.

Types of 2 Stage Air Compressors

A two-stage air compressor is a type of compressor that can compress air to a higher pressure than a single-stage compressor. This type of compressor consists of two cylinders, the first stage being used to compress the air to a lower pressure, and the second stage compressing the air to a higher pressure. This type of compressor is often used for industrial applications that require a higher pressure than a single-stage compressor can provide. The two-stage air compressor is more efficient than a single-stage compressor and is also quieter. This type of compressor is also often used in areas where an even higher pressure is required, such as in manufacturing processes that require high-pressure air. There are several types of two-stage compressors available, including reciprocating piston compressors, rotary screw compressors, and centrifugal compressors. Each type of compressor has its own advantages and disadvantages and the selection of the right type of compressor depends on the specific needs of the application.

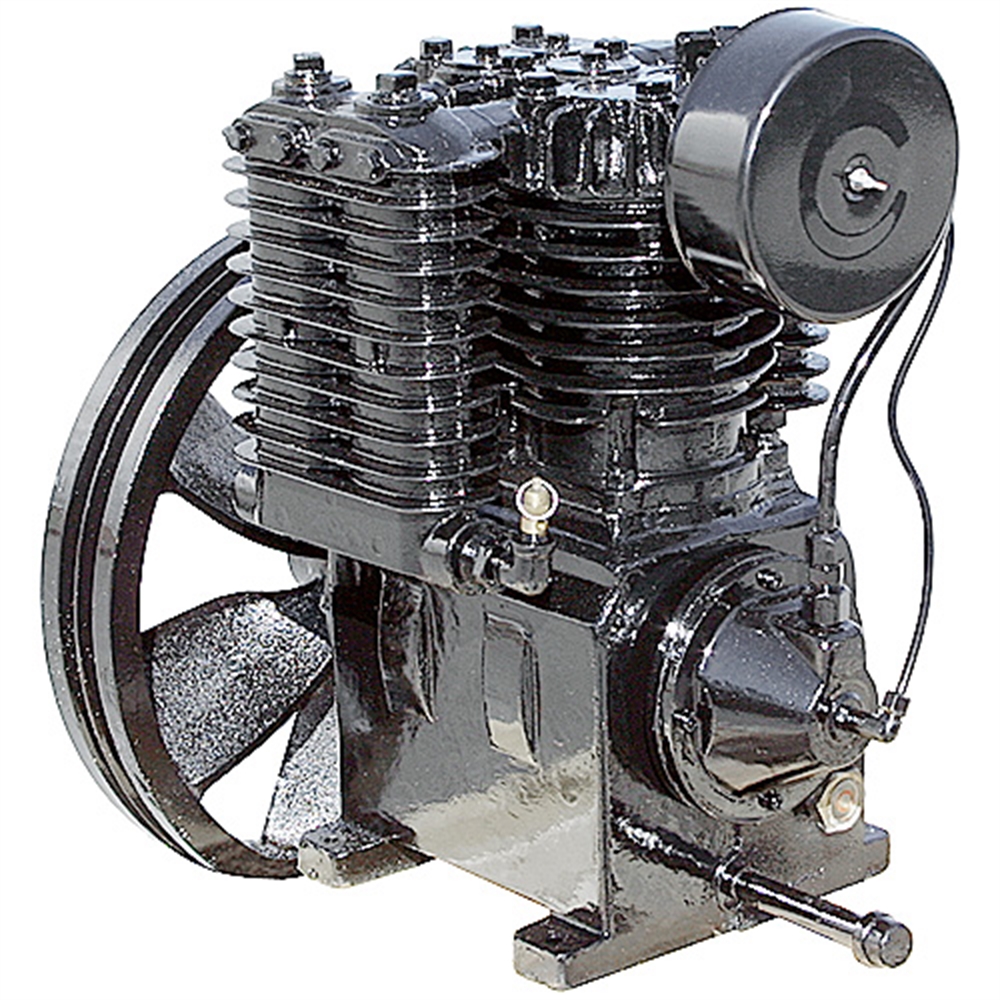

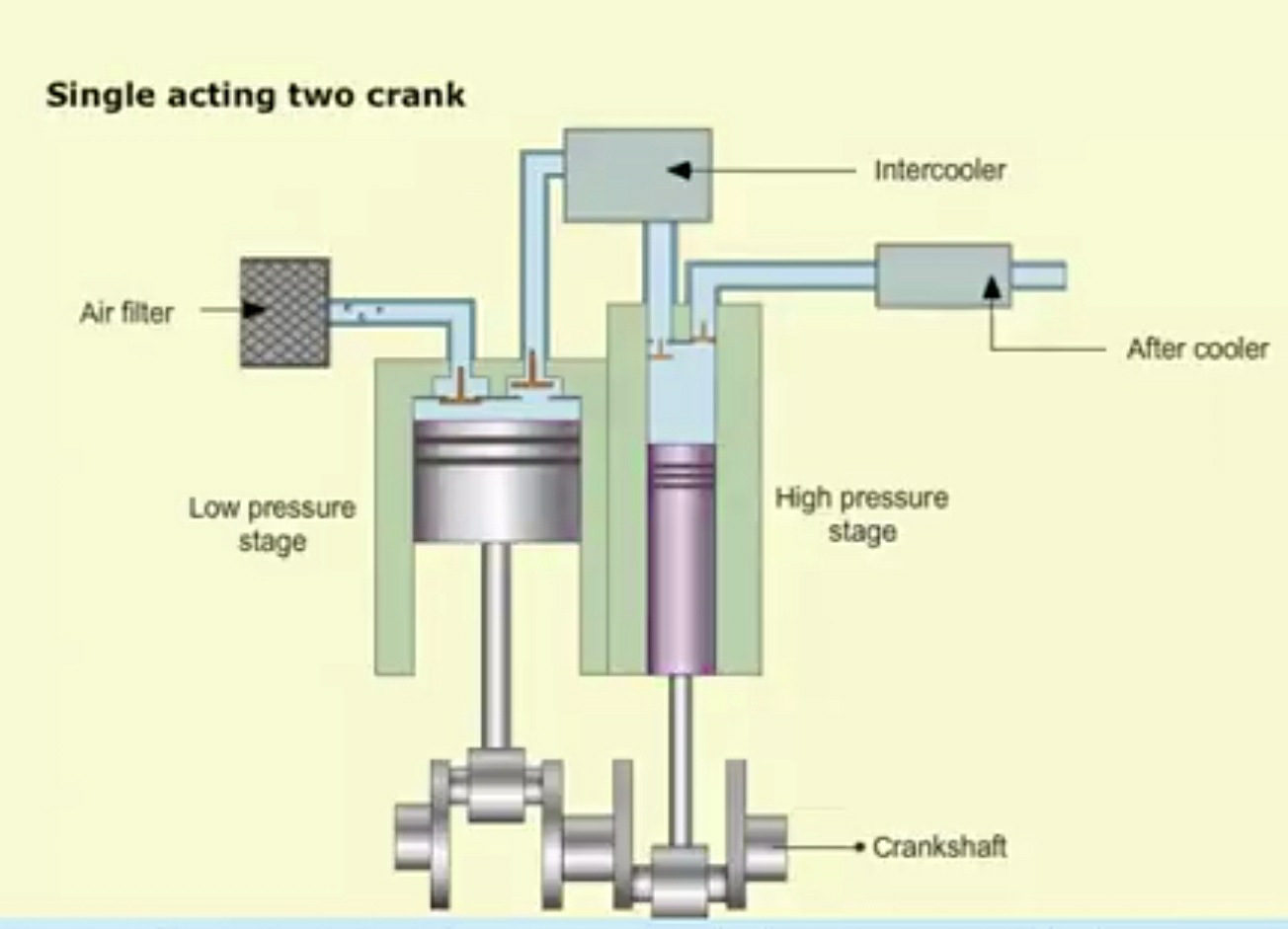

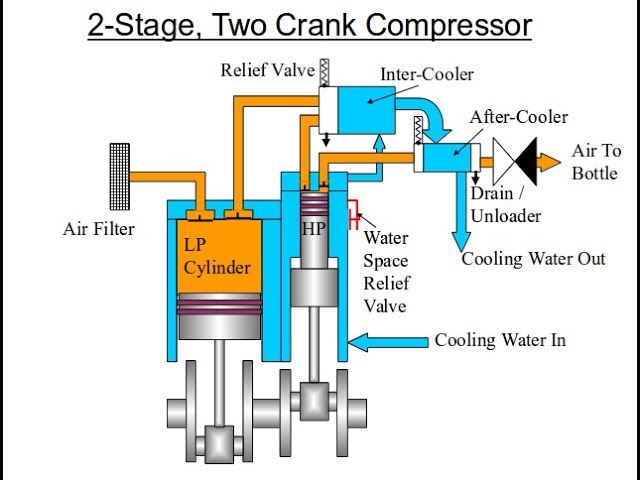

How 2 Stage Air Compressors Work

Stage air compressors are an important component of many industrial processes and are used to generate and store pressurized air for industrial applications. They work by compressing air in two stages to create a higher pressure than a single-stage compressor can generate. The first stage of a two-stage air compressor works by using an electric motor to drive a piston that compresses the air. The piston creates a vacuum that draws air into the cylinder, and the motor compresses the air by pushing the piston back. The air is then discharged into a storage tank at a higher pressure than it was initially. The second stage of a two-stage air compressor consists of a second piston that compresses the air further. This second piston has a higher pressure rating than the first, which allows it to compress the air at a higher pressure. The air is then discharged into the storage tank at a higher pressure than it was initially. This two-stage process allows for higher pressure to be achieved than what a single-stage compressor can generate. The ability to generate higher pressure makes stage air compressors ideal for industrial applications.

Maintenance & Troubleshooting for 2 Stage Air Compressors

Two stage air compressors are a type of air compressor that use two piston stages to compress air. These types of compressors are often used in industrial and commercial settings where a large volume of compressed air is needed. Maintenance and troubleshooting of two stage air compressors is relatively straightforward and can be done with minimal tools and expertise. The most common maintenance item for two stage air compressors is to ensure that the oil level is at the proper level and that the oil is changed regularly. This is especially important for compressors that are used frequently and in harsh environments. The oil should also be changed regularly depending on the type of compressor and the manufacturer’s specifications. Additionally, it is important to check all seals and hoses for wear and tear, as well as to inspect the filter for clogs or dirt. Troubleshooting issues with two stage air compressors can generally be done by checking the electrical connections, testing the voltage, and inspecting for any potential air leaks. If the compressor does not seem to be functioning properly, it is advised to seek professional assistance.

Conclusion

In conclusion, a 2 Stage Air Compressor is an efficient and cost-effective way to power a variety of tools and applications. With the ability to produce more air pressure than a single-stage compressor, it can be used for tasks that require higher pressure than a single-stage compressor can provide. Additionally, the two-stage compressor can provide more consistent air pressure, which can be useful for tasks that require a specific air pressure. When purchasing a 2 Stage Air Compressor, it is important to consider the type of motor, the horsepower, and the CFM rating to ensure that the compressor is powerful enough to meet the needs of the task. Additionally, it is important to consider the tank size, the size of the motor, and the cost of the compressor.