Finding the right size air compressor for your needs can be a daunting task for anyone. With all the different sizes, types, and brands available, it can be difficult to decide which one is best for you. Knowing the size of the air compressor you need and the type of job you need it for is an important factor in determining the right size for your needs. Whether you’re using an air compressor for automotive work, painting, home improvement projects, or industrial applications, the size of the air compressor you need will depend on the job you need it for. A larger air compressor will be more powerful and provide more air volume, while a smaller air compressor will be more efficient and require less energy to operate. Understanding the size and type of air compressor you need will help you make the best decision when it comes to purchasing the right model for your needs.

Understanding Air Compressors

Air compressors are powerful tools used in a variety of industries, from construction to automotive repair. Understanding the basics of how air compressors work and the different types available can help you make an informed decision when choosing the right compressor for your needs. Air compressors use a motor to pressurize air, which is then stored in a tank. Depending on the type of compressor, the motor may be either electric or gas-powered. The more powerful the motor, the larger the tank and the more air pressure the compressor can generate. Air compressors are rated in terms of their CFM (cubic feet per minute) output, which measures the amount of air that can be delivered at a specific pressure. The higher the CFM, the faster the compressor can deliver air. Different types of air compressors are designed for specific applications and require different accessories, such as hoses and fittings, depending on the job. It is important to understand the different types of compressors and their features before making a purchase.

Selecting the Right Size Air Compressor

Selecting the right size air compressor is essential in order to ensure that you have the optimal amount of air power and pressure for your specific application. Air compression is an integral part of many industrial, commercial, and home projects, so it is important to purchase a compressor that is the right size for your needs. There are several factors to consider when selecting the right size air compressor, such as the application, the volume of air needed, and the pressure requirements. When selecting the right size air compressor, it is important to consider the type of work that will be completed. Different types of projects require different amounts of air pressure and volume. For example, a small air compressor can effectively power light-duty tasks such as inflating tires or running air tools, while a larger compressor is better suited for heavy-duty tasks such as sandblasting or operating pneumatic equipment. Additionally, the pressure needs should be taken into account when selecting the right size compressor. Typically, the higher the pressure requirement, the larger the compressor must be. Ultimately, it is important to ensure that the compressor is large enough to provide the right amount of power and pressure for the job.

Factors to Consider When Choosing an Air Compressor

When choosing an air compressor, it is important to consider the size and capacity of the unit, the type of material it is made of, and the power source that is necessary to operate it. The size and capacity of an air compressor determine its ability to deliver a certain volume of air. Larger air compressors can handle larger volumes of air and are capable of providing higher pressures. Additionally, the type of material the air compressor is made of should be considered. Steel and aluminum air compressors are generally more durable and reliable, while plastic air compressors are relatively lightweight and cost-effective.

The power source is another factor to consider when choosing an air compressor. Electrical air compressors are the most common type and are powered through a standard wall outlet. However, for those who require a more portable compressor, a gasoline or diesel engine-powered compressor may be a better option. Additionally, if a compressor will be used in a hazardous environment, an explosion-proof unit may be necessary. Ultimately, selecting an air compressor requires careful consideration of a number of factors to ensure the unit is capable of meeting the user’s requirements.

Calculating CFM and PSI Requirements

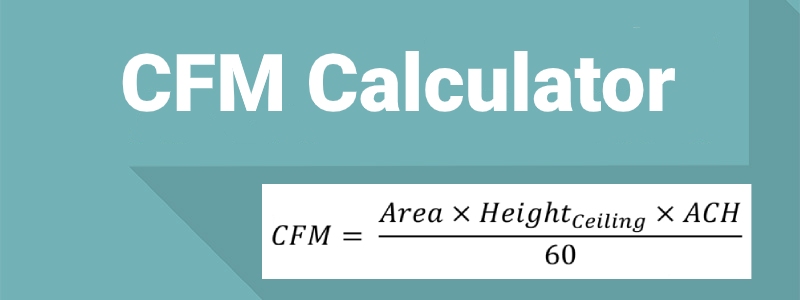

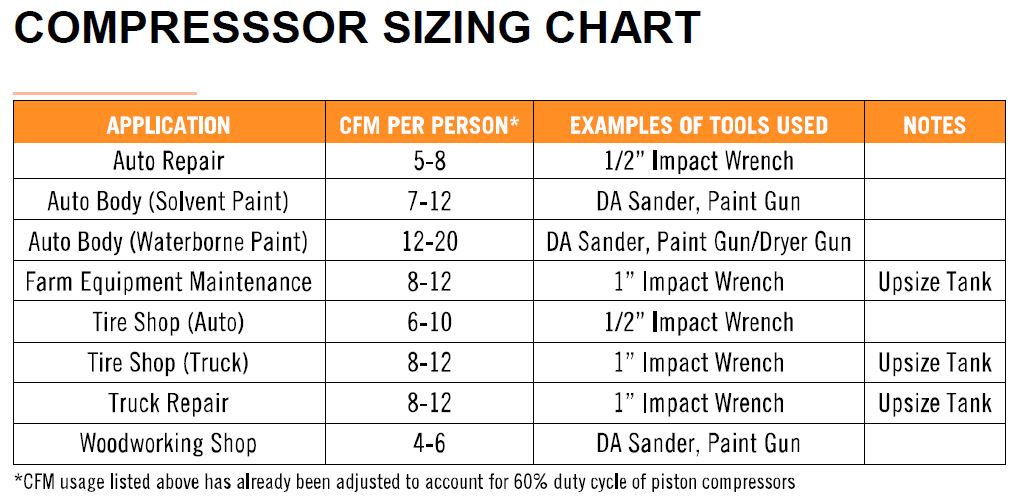

Calculating CFM and PSI requirements is an important part of selecting an air compressor. CFM (Cubic Feet per Minute) is a measurement of air volume flow and PSI (Pounds per Square Inch) is a measure of air pressure. CFM and PSI requirements vary based on the type and size of the tool that is being used. For example, a small pneumatic tool, such as a nail gun, may require a lower CFM and PSI than a larger tool, such as an impact wrench.

When selecting an air compressor, it is important to calculate the CFM and PSI requirements of the tools being used. This can be done by consulting the tool’s manual to determine the CFM and PSI requirements. It is also important to consider the length of the air hose, as this will affect the amount of pressure that is lost when operating the tool. Once the CFM and PSI requirements are calculated, it is easy to select an air compressor that is suitable for the application.

Available Sizes of Air Compressors

The available sizes of air compressors vary depending on the type of compressor and the application it is used for. Generally, air compressors come in a range of sizes from small portable models to larger industrial models. Smaller models are typically used for powering air tools or for inflating tires, while larger models are used for industrial applications such as powering pneumatic systems.

The most common type of air compressor is the rotary screw compressor which typically range from 5 to 300 horsepower. Piston compressors are used for smaller applications and are available in sizes from 1 to 30 horsepower. Portable air compressors are available in sizes from 1 to 5 horsepower and are used for applications such as inflating tires or powering air tools. Industrial grade air compressors are also available in larger sizes and can range up to 1000 horsepower. These are typically used to power pneumatic systems and other industrial applications.

Choosing the Right Brand of Air Compressor

Choosing the right brand of air compressor can be a daunting task, as there are many brands, models, and types of compressors available on the market. It is important to consider all of the different features, benefits, and drawbacks of the different brands available in order to make the best selection. When choosing the right brand of air compressor, the most important factor is to consider the type of application for which the compressor will be used. For example, if the compressor will be used for home improvement projects, an oil-less, direct drive model may be most suitable. If the compressor will be used for industrial applications, a heavy-duty rotary screw compressor may be the best choice.

It is also important to consider the capacity of the compressor and the power source that it uses. The capacity of the compressor should be sufficient to handle the anticipated workload, while the power source should be compatible with the type of application the compressor will be used for. Additionally, it is important to research whether the compressor is rated for continuous duty or intermittent duty, as this can often determine the length of time the compressor will be able to run without requiring maintenance. Ultimately, the right brand of air compressor should be chosen based on the specific needs of the application.

Conclusion

In conclusion, determining the size of air compressor you need for your needs is an important decision that should not be taken lightly. The size of the compressor will depend on the type of job you are doing, the size of your job, and the power needed to complete the task. Taking the time to research the different types of air compressors available, as well as the sizes that are suitable for your project, will help you determine the best size air compressor for your needs.