Compressed Air Pipe Size CFM Chart

To minimize the effect that pressure drop has on your airflow system, you need to install the right-sized compressed air pipes. Be sure to calculate the correct pipe size from the start of your project, to avoid spending a lot more money in the future.

Any kind of obstruction can lead to a pressure drop in your system. Things like a flexible hose, pipe length, quick-connect coupling, and the list go on. These are all things that play a part in the pressure drop through your compressed air system. See more size charts here.

Compressed Air Pipe Size CFM Chart

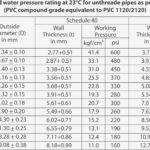

The table below gives the exact pipe size needed for each specific airflow and piping distance. Keep in mind that the pipe size is measured in inches.

[ninja_tables id=”3644″]

The table above measures airflow in CFM (Cubic Feet per Minute) and measures the length of the pipe in feet. The pipe size is measured in inches.

What is a Compressed Air System and Why is Proper Sizing Important?

A compressed air system is basically a bunch of pipes and machines that run on air that’s been squished into a tight little space. It’s a pretty neat way to power all sorts of equipment, from tools to machinery to whole factories. But it’s super important to get the sizing of those pipes just right, otherwise you’re going to have some major problems.

If the pipes are too small, the compressed air won’t be able to flow properly, which can mess up your machines and cost you a lot of money in energy bills. And if the pipes are too big, you’re just wasting money on extra material and installation that you don’t need. Plus, you could end up with all sorts of other problems like condensation and leaks.

So, to make sure your compressed air system is running smoothly, you need to make sure the pipes are the right size for the amount of air you’re trying to move (that’s what we call CFM). Getting the sizing right will help your system work efficiently, keep your energy costs down, and make sure everything is running safely and reliably. And nobody wants to deal with downtime or maintenance costs, right?

Pressure Drop: What it is and How it Affects Compressed Air Pipe Sizing

“Pressure drop” might sound like a new energy drink or something, but it’s actually a pretty big deal when it comes to compressed air pipe sizing. Basically, pressure drop is what happens when the pressure of the air drops as it flows through the pipe. And if you’re not careful, pressure drop can seriously mess up your compressed air system.

So why does pressure drop matter? Well, if the pressure drops too much, it can cause a lot of problems. For one, your machines and tools might not work as well, since they need a certain amount of pressure to function properly. But on top of that, pressure drop can cost you a ton of money in energy bills. That’s because the compressor has to work harder to maintain the right amount of pressure, and that uses up a lot more energy.

When you’re sizing your compressed air pipes, you need to keep pressure drop in mind. If the pipe is too small, the air won’t be able to flow through it as easily, and that can cause a lot of pressure drop. On the other hand, if the pipe is too big, you might not have enough air flow to create the pressure you need.

So the key is to find the sweet spot where you have enough air flow to maintain the right pressure, but not so much that you’re wasting energy. That means taking into account things like the length of the pipe, the type of fittings you’re using, and how many twists and turns the pipe has. It might sound complicated, but if you get it right, you’ll have a compressed air system that works like a dream.