DIY Guide: Building Running Boards for 2016 Dodge Ram in 7 Easy Steps

Are you looking to add some extra style and functionality to your 2016 Dodge Ram? Running boards are a great way to improve the look of your vehicle, while also providing a practical step for you and your passengers to get in and out of your truck with ease. Purchasing running boards from a dealership or aftermarket supplier can be expensive, but with this DIY guide, you can build your own running boards in just seven easy steps. Not only will building your own running boards save you money, but it can also be a fun and rewarding project to take on. With a few basic tools and materials, you can create a custom set of running boards that perfectly match your style and the look of your truck. Whether you’re an experienced DIYer or new to the world of automotive projects, this guide will provide you with all the necessary steps and tips to create your own running boards for your 2016 Dodge Ram.

The article titled \DIY Guide Building Running Boards for 2016 Dodge Ram in 7 Easy Steps\ is a comprehensive and informative guide that outlines the steps required to build and install running boards on a 2016 Dodge Ram. The article begins with a brief introduction to the importance of running boards and why they are necessary for a truck like the Dodge Ram. It then proceeds to detail the materials and tools required for the project and provides a step-by-step guide to building the running boards. The instructions are easy to follow and include helpful tips and suggestions to ensure that the project is completed smoothly. The article concludes by highlighting the benefits of having running boards on a truck and encouraging readers to take on the DIY project themselves.

Running boards play a vital role in enhancing the appearance and functionality of your Dodge Ram. These boards not only add to the aesthetic appeal of your truck but also serve as a safety measure, especially for children and the elderly. Running boards provide a stepping platform that makes it easy to get in and out of the vehicle, and they also protect your truck from debris and road hazards. Additionally, running boards can help improve the aerodynamics of your Dodge Ram by reducing wind resistance and drag, which can improve fuel efficiency. Overall, having running boards for your Dodge Ram is an essential investment that can make your truck more accessible, safe, and efficient.

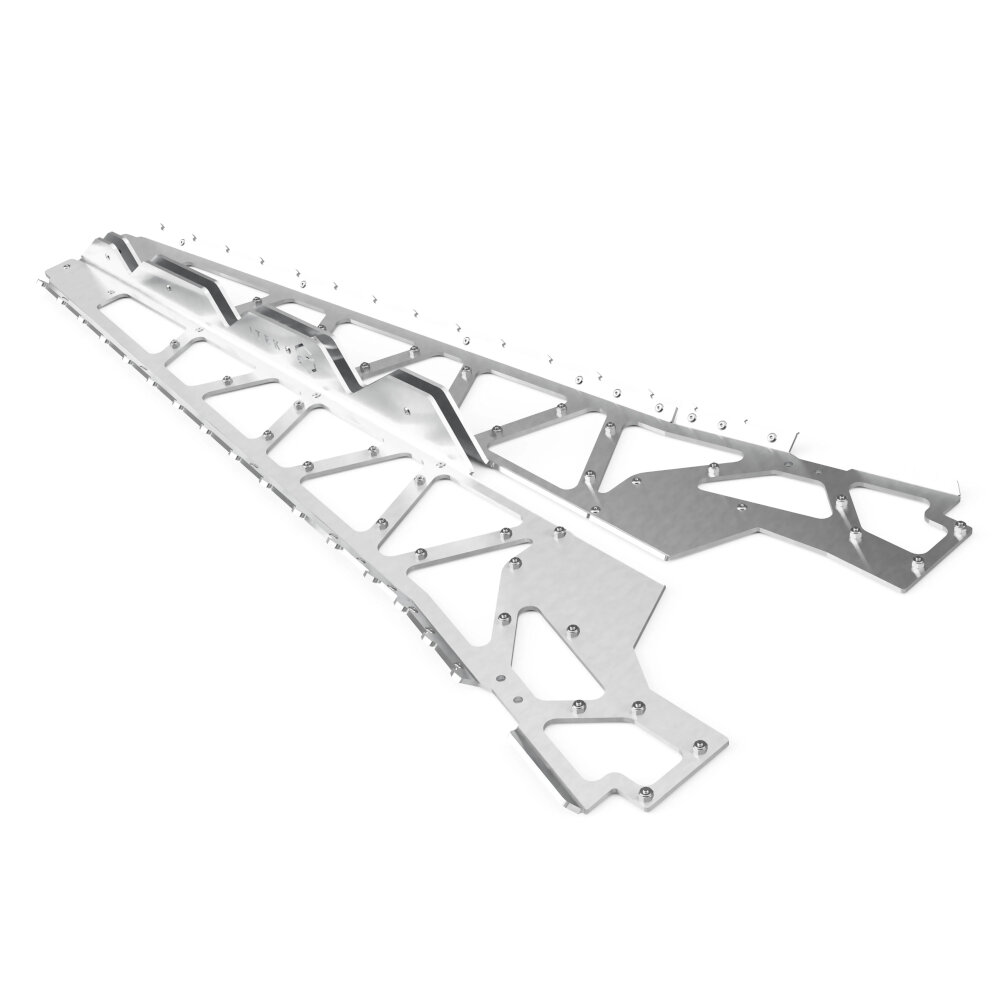

In order to build running boards for a 2016 Dodge Ram, there are several materials that are required. Firstly, you will need a measuring tape and a marker to take accurate measurements for the size of the running boards. Next, a saw or a jigsaw will be required to cut the aluminum or steel sheets to the appropriate size. Additionally, a drill and drill bits will be necessary to create holes for the bolts and screws that will hold the running boards in place. Furthermore, you will need nuts, bolts, and screws to attach the running boards to the truck. Finally, sandpaper and a paintbrush will be needed to sand and paint the running boards to provide a smooth finish. With these materials on hand, building running boards for a 2016 Dodge Ram can be a simple and straightforward project.

Step 1: Measure and Cut

The first step in building running boards for your 2016 Dodge Ram is to measure and cut the necessary materials. This is a crucial step as it determines the overall size and shape of your running boards. Measure the length and width of your truck’s chassis, taking into account any curves or angles. This will give you a rough idea of the size of the running board needed. Once you have the measurements, use a jigsaw or circular saw to cut the material to the desired size. Be sure to wear protective gear such as gloves and safety goggles when cutting the material. When cutting the materials, it’s important to pay attention to any specific design features you want to incorporate. For example, you may want to add a lip or edge to the running board to prevent slipping. Or, you may want to create a decorative pattern or design on the surface of the running board. Take your time and use a measuring tape to ensure that each cut is precise and accurate. Once you have all the materials cut to size, you can move on to the next step of the process. Remember, taking the time to measure and cut your materials correctly will ensure a sturdy and safe set of running boards for your 2016 Dodge Ram.

Before starting the process of building running boards for a 2016 Dodge Ram, it is essential to measure the length and width of the running board. This step ensures that the running board is compatible with the truck’s size and that it will fit securely. To accurately measure the length of the running board, use a measuring tape to measure from the front to the back of the truck’s cab. Similarly, to measure the width, measure the distance between the truck’s wheel wells. It is crucial to take precise measurements to avoid any issues during the installation process and to ensure the final product meets the desired specifications.

Cutting the board according to the measurement is an essential step in building running boards for the 2016 Dodge Ram. It is imperative to ensure that the board is cut accurately to fit the length of the vehicle. To do this, measure the length of the Dodge Ram carefully and mark the board with a pencil or marker at the appropriate length. Use a circular saw or jigsaw to cut the board along the marked line. It is vital to wear safety goggles and gloves while cutting the board to prevent any injury. After cutting the board, sand the edges to get rid of any roughness or splinters. This step is crucial to ensure that the board fits seamlessly onto the vehicle and looks professional.

Step 2: Sanding and Smoothing

After measuring and cutting the running boards to the desired length and shape, the next step in building running boards for a 2016 Dodge Ram is sanding and smoothing. Sanding is a vital step in the process of building running boards because it helps to remove any rough edges or uneven surfaces that may cause injury or damage to the vehicle. Sanding also helps to ensure that the painted surface adheres properly to the running board, creating a smooth, even finish. To begin sanding, use a medium-grit sandpaper to remove any rough edges or burrs from the edges of the running board. Be sure to sand evenly across the entire surface of the board to ensure a smooth finish. Next, switch to a fine-grit sandpaper and continue sanding until the surface of the board is completely smooth. It is important to take your time during this step, as any rough or uneven surfaces will be visible once the running boards are installed on the vehicle. Once the sanding is complete, wipe the running boards clean with a damp cloth to remove any dust or debris, and allow them to dry completely before moving on to the next step.

Sanding the edges of the board is a crucial step in building running boards for your 2016 Dodge Ram. It ensures that the edges are smooth and free from splinters, giving your boards a neat and professional finish. To sand the edges, you will need to use sandpaper with a fine grit to avoid damaging the wood. Take your time and work carefully, paying attention to the corners and curves to ensure the edges are sanded evenly. Once you have finished sanding, use a clean cloth to wipe away any dust or debris, and your boards will be ready for the next step in the building process.

Once the board has been cut to size, it’s time to smooth the surface. This step is important for both aesthetic and practical reasons. A smooth surface will give the running board a professional, finished look. Additionally, a smooth surface will be less likely to catch on shoes or clothing, making it safer to use. To smooth the surface of the board, start by using a coarse grit sandpaper to remove any rough spots or splinters. Then, switch to a finer grit sandpaper to achieve a smoother finish. Take care to sand evenly across the surface, being sure to check for any areas that might need extra attention. Once the surface is smooth, wipe it down with a damp cloth to remove any dust or debris.

Step 3: Drilling Holes

Step 3 of the DIY guide to building running boards for a 2016 Dodge Ram is drilling holes. This step is crucial to ensure that the running boards are securely attached to the truck. It is important to use the right drill bit size, which is usually indicated in the instructions that come with the running board kit. It is also essential to make sure the holes are drilled in the right location, as any errors can result in the running board being misaligned or unstable. A drill with a level is recommended to ensure accuracy. When drilling holes, it is important to wear protective gear such as safety goggles and gloves. It is also advisable to have a vacuum cleaner nearby to clean up any debris that may result from drilling. After drilling the holes, it is important to check that they are the correct size and that the running board fits properly. If there are any issues, it is best to address them before moving on to the next step. Overall, drilling holes may seem like a simple step, but it is crucial to ensure the safety and stability of the running boards, which in turn ensures the safety of the driver and passengers.

Before starting the installation process of running boards on your 2016 Dodge Ram, it is essential to determine the location of the mounting brackets. This step is crucial as it ensures that the brackets are placed correctly, allowing the running boards to be securely attached to the vehicle’s body. To begin, identify the correct mounting points by referring to the manufacturer’s instructions or by using a measuring tape to locate the correct distance from the vehicle’s frame. Once you have identified the mounting points, use a marker or a piece of tape to mark the spot. Double-check the location before drilling the holes for the brackets. With the correct placement, the running boards will provide a safer and more comfortable entry and exit experience for the vehicle’s passengers.

Drilling holes for the mounting brackets is a crucial step in building running boards for your 2016 Dodge Ram. It requires precision and accuracy to ensure that the brackets are properly secured. Before drilling, it is important to measure and mark the exact location where the brackets will be attached. A drill with the appropriate bit size should be used to create the holes. It is recommended to start with a smaller drill bit and gradually increase the size until it matches the diameter of the bolts being used. It is also important to clean any debris that may accumulate in the holes to prevent any obstruction during installation. Once the holes are drilled and cleaned, the mounting brackets can be attached securely, ensuring that your running boards are safe and stable.

Step 4: Installing Brackets

In Step 4 of the DIY Guide Building Running Boards for 2016 Dodge Ram in 7 Easy Steps, the installation of brackets is crucial for the secure and stable attachment of the running boards to the vehicle. Brackets are essential components that ensure the running boards are firmly held in place and can support the weight of the passengers getting in and out of the truck. To install the brackets, start by placing them underneath the truck, ensuring they are aligned with the mounting holes. Secure the brackets using bolts and nuts, tightening them with a wrench to prevent any looseness. It is important to ensure that the brackets are level and evenly spaced, as any errors in their installation can lead to instability or damage. When installing the brackets, it is essential to use the correct tools and follow the manufacturer’s instructions. Failure to do so can lead to inaccurate installation, which can be dangerous for the passengers and the vehicle. Additionally, it is crucial to ensure that the brackets are compatible with the make and model of the vehicle, as using the wrong brackets can lead to further complications. By installing the brackets correctly, the running boards will be able to provide a safe and comfortable step for passengers getting in and out of the truck, adding to the functionality and aesthetics of the vehicle.

Once you have measured and marked the appropriate placement for your running boards, it’s time to get started on installing the mounting brackets. Begin by ensuring that the brackets are level and aligned according to your markings. Double-check that the brackets are facing the correct direction, and that the holes on the brackets align with the holes on the board. Once you’re satisfied with the positioning, use a drill and the appropriate screws to securely attach the brackets to the board. Make sure to tighten the screws firmly to avoid any wobbling or instability. Installing the mounting brackets is a crucial step in building your running boards, as they provide the necessary support for the board to hold weight and endure wear and tear over time.

After measuring and cutting the aluminum material to the desired length, the next step in building running boards for the 2016 Dodge Ram is attaching the brackets. This crucial step ensures the stability and durability of the running boards. It’s important to use a level to ensure the brackets are attached evenly on both sides. Once the brackets are securely fastened, the running board can be attached to them using bolts and nuts. It’s recommended to double-check the alignment and stability of the running board before testing it out. Properly attaching the brackets is a crucial step in building sturdy running boards that can withstand weight and pressure.

Step 5: Painting and Finishing

After completing the previous steps, it’s time to give your running boards a touch of personality. Painting and finishing are the final steps to make your DIY running boards look visually appealing. Before starting this step, make sure you have all the necessary tools and materials, including sandpaper, primer, paint, and clear coat. Start by sanding the running boards to ensure a smooth surface, then apply the primer. Once the primer has dried, it’s time to add the final coat of paint. Choose a color that matches your truck or something that stands out. You can add a personal touch to the running boards by using a stencil or a decal. After the paint has dried, give the running boards a clear coat to protect the paint and give it a glossy finish. The painting and finishing step is where you can let your creativity shine. If you want a rugged look, consider using a textured paint or adding a matte finish. For a more polished look, use a high-gloss paint or add chrome accents. The key is to choose a finish that fits your personal style and complements your truck. Don’t forget to take your time and apply the paint and clear coat evenly to ensure a professional-looking finish. Painting and finishing the running boards is the final step in the DIY process, and once completed, your truck will have an upgraded look that you can be proud of.

Before you start painting your running boards for the 2016 Dodge Ram, it’s important to apply a coat of primer to the board’s surface. This step is crucial as it prepares the surface for the paint to adhere correctly, ensuring a smooth and long-lasting finish. The primer acts as a bonding agent between the surface and the paint, preventing any peeling or chipping that may occur over time. It also helps to seal any small cracks or imperfections on the surface, creating a smoother base for the paint to adhere to. Applying primer is easy and can be done using a brush or spray can. Once applied, allow the primer to dry completely before applying the final coat of paint.

Once the running boards are properly cut, sanded, and primed, the next step is to paint them with the desired color. This is a crucial step in making sure that the running boards blend seamlessly with the rest of the truck’s exterior. Before painting, it’s important to make sure that the surface is clean and free of any debris or dust. A high-quality paint designed for automotive use should be used to ensure durability and longevity. The paint should be applied in thin, even coats, allowing each coat to dry completely before applying the next. Once the final coat has been applied and has dried, the running boards will be ready to install and provide a sleek, customized look to the 2016 Dodge Ram.

After completing the construction of your running boards for the 2016 Dodge Ram, it’s essential to apply a clear coat for protection against weathering, UV rays, and scratches. A clear coat is a transparent layer of paint that helps to preserve the paint underneath it. It also gives a glossy and shiny finish to your running boards. To apply the clear coat, you will need to sand the surface of the running boards with a fine-grit sandpaper to remove any debris and roughness. Then, clean the surface with a degreaser and wipe it dry. Apply the clear coat in thin layers, allowing each layer to dry before applying the next one. It’s best to apply at least two coats of clear coat to ensure maximum protection and durability. Once the clear coat is dry, your running boards will have a protective layer that will keep them looking like new for years to come.

Step 6: Adding Grip Tapes

Step 6 of the DIY guide for building running boards for a 2016 Dodge Ram involves adding grip tapes to ensure safety and stability when stepping on the boards. Grip tapes are essential for preventing slips and falls, especially during wet conditions. The grip tapes are made of a coarse material that provides traction and grip to shoes or boots, making it easier to step on and off the running board. They are easy to apply and come in different sizes, shapes, and colors to match the design of the running board. The process of adding grip tapes involves cleaning the surface area of the running board using soap and water to remove any dirt or debris. After cleaning, the grip tapes are then cut to the desired size and shape that will fit perfectly on the running board. It is important to ensure that the edges of the grip tapes are aligned with the edges of the running board to prevent any peeling or lifting. Once the grip tapes are in place, press them firmly to ensure they stick properly. Adding grip tapes to the running board not only provides safety but also adds a stylish touch to the design of the running board.

Cutting grip tapes to fit the board is an essential part of building a running board for your 2016 Dodge Ram. Grip tapes provide the necessary friction and grip to prevent you from slipping or losing your footing while getting in and out of the truck. It is important to measure the length and width of the board accurately before cutting the grip tape to ensure a perfect fit. Using a sharp utility knife or scissors, cut the grip tape to size, making sure to leave some extra material around the edges. Carefully apply the grip tape to the board, smoothing out any bubbles or wrinkles as you go. With a properly fitted and secured grip tape, you can confidently step onto your running board with the assurance of a firm footing.

Once you have cut your running board to fit your 2016 Dodge Ram, it’s time to start applying the grip tape. Grip tape is essential to ensure that your feet do not slip while getting in and out of the truck. Begin by cleaning the surface of the board, removing any debris or dust that may affect the grip tape’s adhesion. Next, carefully apply the grip tape, ensuring that there are no air bubbles or wrinkles. Use a utility knife to trim the excess tape, giving your board a clean and professional look. Remember, the grip tape is what keeps you safe, so take your time and make sure it’s applied correctly.

Step 7: Final Touches

In the final step of building running boards for a 2016 Dodge Ram, it is important to pay attention to the smallest of details to ensure a seamless finish. This step includes adding the final touches to the running boards, which can greatly enhance their appearance and functionality. The first thing to do is to check for any rough edges or imperfections and sand them down to create a smooth and polished surface. This will not only improve the look of the running boards but also protect against rust and corrosion. After sanding, applying a coat of primer and paint will give the running boards a professional and finished look. Choosing a paint color that matches the color of the truck will create a cohesive and uniform appearance. It is important to use high-quality paint that is resistant to chipping and fading to ensure the running boards maintain their appearance for a long time. Lastly, adding non-slip material to the top of the running boards will provide safety and prevent any accidents from occurring. With these final touches, the running boards will not only serve a functional purpose but will also add to the aesthetics of the truck.

One crucial step in building running boards for your 2016 Dodge Ram is to ensure that all screws and bolts are tightened properly. Loose screws and bolts can compromise the safety and stability of the running boards, leading to potential accidents or damages. It is recommended to use a torque wrench to tighten the screws and bolts to the manufacturer’s specifications, ensuring that they are securely fastened. Additionally, you should periodically check the tightness of the screws and bolts after installing the running boards to ensure that they remain secure over time. By taking the time to properly tighten all screws and bolts, you can have peace of mind knowing that your running boards are safely and securely installed on your vehicle.

When building running boards for your 2016 Dodge Ram, it’s essential to ensure that they are stable and durable. The stability of your running boards will be determined by the type of material you use to construct them and how well you anchor them to your truck. Using high-quality materials such as steel or aluminum will ensure that your running boards can support your weight and the weight of your passengers without bending or breaking. The durability of your running boards will be determined by their ability to withstand wear and tear from regular use, exposure to the elements, and potential damage from road debris. By selecting durable materials and properly sealing and finishing your running boards, you’ll ensure that they last for years to come and continue to add functionality and style to your truck.

To build running boards for a 2016 Dodge Ram, there are seven easy steps to follow. Firstly, measure the length and width of the running board area and then create a design and template based on those measurements. Secondly, cut the steel and aluminum planks according to the design and template. Thirdly, drill holes in the planks for the brackets to be attached. Fourthly, attach the brackets to the planks using bolts and nuts. Fifthly, attach the brackets to the truck frame using bolts and nuts. Sixthly, install the end caps to the planks. Finally, add a non-slip surface to the planks to make them safer to use. By following these seven easy steps, anyone can build running boards for their 2016 Dodge Ram.

In conclusion, building running boards for your 2016 Dodge Ram is a project that can be accomplished with some basic tools and a bit of patience. It can be a rewarding DIY experience that not only saves you money but also gives you a sense of accomplishment. However, it is important to take the necessary safety precautions and follow the steps carefully to ensure that the running boards are installed correctly. Additionally, it is recommended to consult with an expert or someone with experience in car modifications if you encounter any difficulties during the process. With these tips in mind, go ahead and give your Dodge Ram a stylish and practical upgrade with your very own custom-made running boards.

Conclusion

In conclusion, building running boards for your 2016 Dodge Ram is not only a cost-effective solution but also a fun DIY project that can be accomplished in just seven easy steps. By following the guide we have provided, you can enhance the functionality and appearance of your vehicle while also gaining a sense of satisfaction from completing the project yourself. With the right tools and materials, anyone can create custom running boards that perfectly suit their needs and preferences. So why not give it a try and take your Dodge Ram to the next level?